Blanking Panels: The Ultimate Guide

Data center management is all about making sure hot and cold air are properly regulated so that your equipment is kept in the ideal condition for efficient functioning.

Various strategies are used to keep the various parts of data centers at their perfect respective temperatures, such as cold aisle containment. But the real key to temperature and airflow management is the use of server rack blanking panels.

When blanking panels are properly installed in the right places in the server room, the airflow in your data center is improved significantly. It can even help increase the efficiency of your power consumption and lead to lower energy costs.

So, what exactly are blanking panels, and how do they work to improve the airflow in your data center? Read on below for everything you need to know about this handy data center management tool.

In the article:

[—ATOC—]

[—TAG:h2—]

What are Blanking Panels?

When setting up the server room in your data center, one of the most important factors to keep in mind is to avoid leaving empty spaces in between pieces of equipment on the server racks. This negatively affects airflow conditions and can lead to a variety of problems.

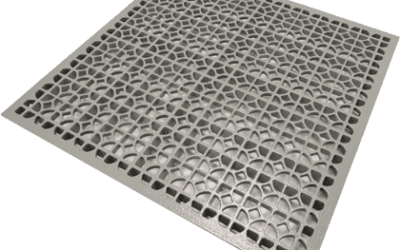

Instead, you can use blanking panels to fill in the gaps. A blanking panel is a simple sheet, usually made of metal or plastic, that can occupy an empty space on a server rack until there is a piece of equipment ready to take its place.

When this metal or plastic material comes into contact with the air around it, it can manipulate hot and cold air differently to allow for perfectly regulated temperature and airflow.

Why Does Your Data Center Need Server Rack Blanking Panels?

Blanking panels are the only solution to poor airflow and unregulated temperatures around your servers.

If you’re experiencing increased temperatures around your server racks, making sure to fill in the gaps with blanking panels can produce much-needed cooling effects that will support the well-being and efficiency of your data equipment.

Prevent Buildup of Hot Air

The main purpose of blanking panels is to improve the flow of air around the server rack so that hot air can escape instead of getting trapped and overheating the machines.

Server rack cooling is an essential part of data center management, so it’s important to install blanking panels in all the right places so that hot air doesn’t stick around and overhead your equipment.

Improve Airflow Management

One crucial benefit of the installation of blanking panels on your racks is improved ventilation. This is extremely helpful with mitigating excess heat and cooling down your equipment to prevent a malfunction.

Blanking panels are specially designed to remove unwanted heat from the rack. When hot air hits the panel, it is pushed up and away from the panel, cooling down the rack in the process.

Protect Data Equipment

Having tool-less blanking panels installed throughout your rack units is the best way to keep all of your machines securely stored and safe from unregulated temperatures. A blanking panel on the rack is a great defense against several devastating but easily avoidable data center issues.

In addition to the above points, a cleaner rack also goes a long way towards keeping your equipment free of harmful dust.

What Can Happen If You Don’t Use Blanking Panels?

If you don’t fill in the unused spaces on a server rack with blanking panels, this can lead to a whole host of problems, among them uneven cooling and inefficient power usage.

But those aren’t the only issues a simple blanking panel can save you from. Below are four of the most common problems that result from improperly managing server rack units.

Tornado Effect

Without a tool-less blanking panel in place, air can blow into the opening between two pieces of equipment on the rack and start spinning in place, unable to escape. This can trap unwanted warmth on your server rack and eventually cause your machines to overheat.

Keeping panels in the right places prevents this problem by blocking the opening and allowing air to escape overhead.

Dead Spots

Open spots on the rack can also disrupt the movement of air, creating an area where no air can flow through the space from one side to the other. This can lead to a buildup of warmth in an inopportune place, which can cause serious problems with your machines if left unattended.

Air Pulled from Wrong Direction

It’s important for any air flowing through the racks to move only in one direction. Namely, cool air should move into the rack and warm air should move out of the rack. This keeps the machines from overheating and regulates the temperature in the data center.

Installing tool-less blanking panels in the right spots facilitates this movement and prevents air from blowing in the wrong direction.

Inefficient Use

Without the benefits provided by these blanking panels, your data equipment will likely run inefficiently, slowing down the works for your whole operation. Luckily, simply installing a few panels should be enough to turn things around for the better.

What’s the Difference Between Blanking Panels and Filler Panels?

If you’ve ever heard of filler panels before, you may be a tad confused at this point. Is there a difference between blanking panels and filler panels?

Nope, there is no difference. These are just two different terms that refer to the same type of panel.

Whatever you call it, a blanking panel is a necessary tool to keep your server rack in good condition and your data equipment safe from harm.

Protect Your Data Equipment with Server Rack Blanking Panels

The most important thing you can do to support your server racks is to make sure the air around them can flow freely and that the temperature is properly regulated.

The best way to accomplish this is to install airflow management blanking panels in any unused rack space that may arise in your server cabinet.

So go ahead and take the next step towards protecting your servers and buy data center cooling equipment such as blanking panels today!